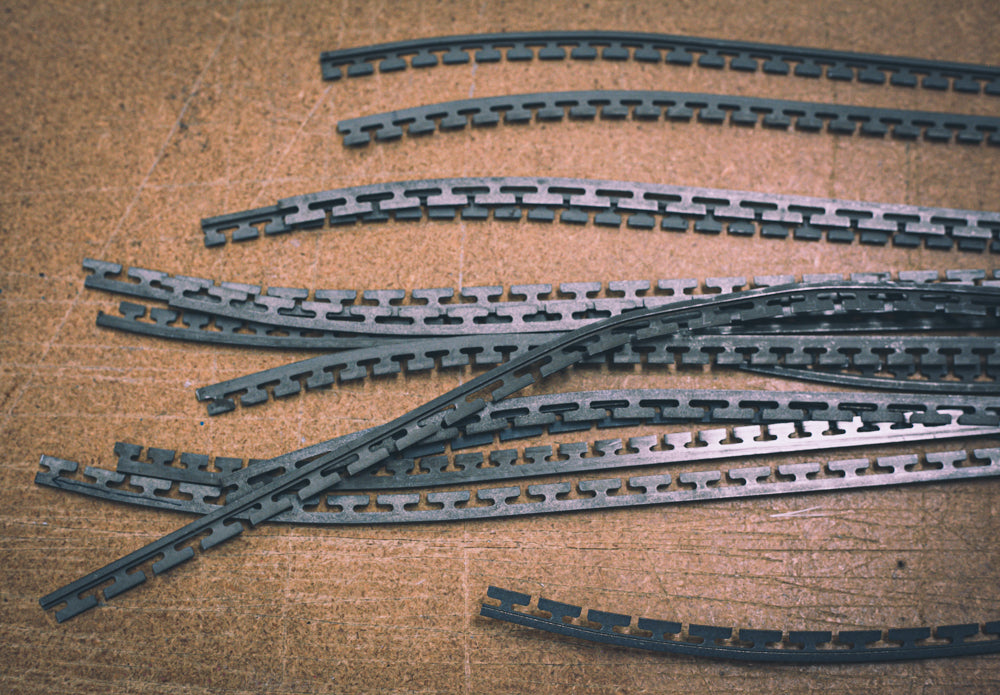

Welcome to Our R&D Workshop

Pallas Snowboards started in a small workshop near downtown Salt Lake City, Utah in Fall 2013. Our friends at Chimera Snowboards invited us to share their workshop and tools, mentoring us in the craft of building snowboards and splitboards.

While our ambitions and skills have grown since our early days, our shop size has not. In fact, we moved to an even smaller workshop with Chimera in 2016 as a way to get closer to our grassroots philosophy. If it looks like the inside of a garage, that’s because it is.

In 2018, we moved our manufacturing to a large-scale factory to help us bring more boards to the world. However, we still continue to prototype new shapes and refine existing ones from our Salt Lake City workshop.

Pallas and Chimera have always been an after-hours side project, and our backyard garage is a place for us to work with our hands after coming home from working a 9-5. (That’s why you’ll find us here late at night and why you won’t find us answering the phone during the day…or ever.)

We sketch out new designs and check emails on the same work benches where we glue edges and drill inserts. (The air compressor comes in handy to dislodge fiberglass from the keyboard.) Our fridge is notoriously understocked with 3.2% beer and La Croix. Our sticker door is growing, but could use some help.

There’s an order to our chaos, and we try to keep it tidy, but if you’re new to the shop, good luck figuring out our method. Our single snowboard press has churned out hundreds of award-winning shapes, new prototypes, and failed experiments, but no tool works harder than a nondescript piece of plastic that’s labeled “THIS IS A TOOL” so we don’t throw it away.